Our company has won support of 50 million forints under the New Széchenyi Plan tender! The project name is "LEMEZTECHNOLÓGIAI BESZÁLLÍTÓ VÁLLALKOZÁS KAPACITÁSBŐVÍTŐ ÉS GAZDASÁGOSSÁG NÖVELŐ BERUHÁZÁSA KOMBINÁLT STANC-LÉZER GÉP BESZERZÉSÉVEL" (Expansion of capacity and increase of the economy of a sheet metal supplier by acquiring a combined punching-laser machine).

Description:

Technology development of micro, small, and medium enterprises - GOP-2011-2.1.1-11/B project: Acquisition of a combined punching-laser machine

Name of the device:

TruMatic 3000 fiber (K04) CNC combined machine for medium-sized panels

Technical data:

-Working width: 2500×1270 mm

- Stable, easily accessible "C" frame

- Coordinated control for high-precision processing

- 18-stage tool magazine with 2 sheet clamps

- Drive with maintenance-free 3-stage motors

- Brush tables

- Part slide with 300×500 mm

Name and contact of the beneficiary:

MATIC Kft.

Alkotmány u. 7, 6066 Tiszalpár, Hungary

Tel: 76/424-015

Place of implementation:

6066 Tiszalpár, Köztársaság u. 11. Hrsz .: 737

Name and contact of the participating organization:

MAG - Magyar Gazdaságfejlesztési Központ Zrt.

1139 Budapest, Váci út 81-83.

1539 Bp. pf.:684

National Development Agency

06 40 638 638

|

|

|

|

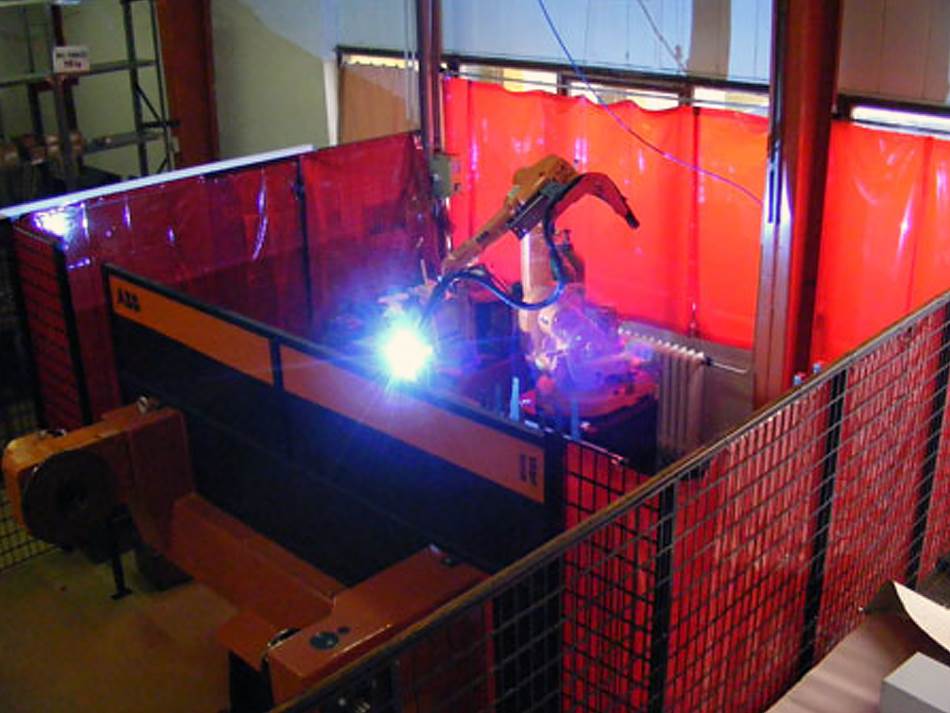

Under the tender for the technology development of micro, small, and medium enterprises - GOP-2009-2.1.1/A, our company has successfully applied for the acquisition of a complete industrial robot welding cell ABB IRB 1600.

Participating organization in the tender:

MAG - Hungarian Center for Economic Development AG

1139 Budapest, Váci út 81-83.

Tel.: 40/200-617

With the commissioning of the welding robot, our company has made a qualitative leap in the field of welding technology, which contributes to strengthening our market position. It allows the integration of new partners and the production of new products.

The advantages of welding with the welding robot are:

- Uniform weld quality - the uncertainty of manual welding can be avoided.

- Reduction of production time.

- The heat load on the workpiece is reduced, minimizing warping and deformation.

- Spray-free processing reduces post-processing time and costs.

The ABB IRB 1600 welding robot is designed for cost-effective performance in various applications. It is easily adaptable to workpieces and has a working range of 1200x1600. The IRC5 controller is easy to program and provides a user-friendly interface.

The welding robot has very precise positioning and reliability as well as good traceability. Its design allows for consistent performance (+0.05 mm) even under the most difficult conditions.

It has a short cycle time and is one of the fastest robots in its category. It is particularly well suited for large quantities, curved welds, and complicated seam patterns - the versatile robot meets all industrial requirements.

|

|